Precision Metallographic Analysis

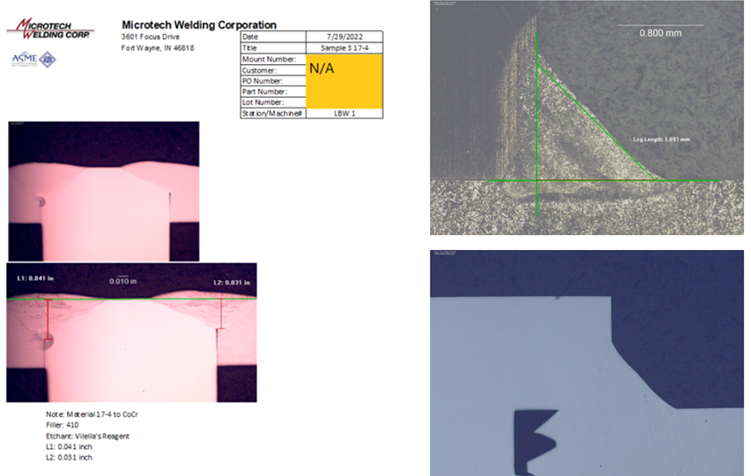

At Microtech Welding Corporation, our in-house cross-sectioning lab supports our commitment to precision and quality in every weld. This specialized area within our operations is crucial for weld verification and drives our ability to maintain the highest standards in welding processes.

Our lab is a significant asset for new development projects, especially when working with challenging base metals that require specialized welding procedures. The lab enables our team to weld and verify samples, ensuring they meet all specified requirements.

Our process:

1. Initial welds are analyzed for any anomalies.

2. If issues are detected, welding settings are adjusted.

3. New samples are created using updated settings and re-evaluated.

4. This cycle continues until the weld meets all acceptance criteria.

This meticulous approach guarantees the highest quality in every weld we produce.

Advanced Validation Capabilities

Our lab equipment isn't just for development—it's also crucial for validations:

We verify high and low settings for Operational Qualifications.

Tests are performed at nominal settings for Process Qualifications.

Our equipment allows for precise measurements and analysis of weld characteristics.

Driving Quality

At Microtech Welding, our Cross Sectioning Lab capability is integral to our operations—it's a testament to our commitment to quality. By combining technology with our team's expertise, we're able to:

- Develop new welding procedures for challenging materials

- Validate and improve existing processes

- Provide our clients with unparalleled confidence in weld integrity

Whether you're in aerospace, medical device manufacturing, or any industry requiring precision welding, Microtech Welding's cross-sectioning capabilities ensure that your welds meet the highest standards of quality and reliability.