Tungsten Inert Gas (TIG) - GTAW

At Microtech, we provide Tungsten Inert Gas (TIG) welding - also known as GTAW - for applications requiring stronger, deeper penetration welds on thicker materials.

TIG welding is commonly used by customers in medical, aerospace, food processing, and tool & die industries where structural integrity is critical.

What is GTAW?

TIG welding uses a non-consumable tungsten electrode to create an arc between it and the parent material while using a shielding gas, typically Argon. When the arc is struck, a weld puddle is formed and can fuse two materials together, or a filler material can be added. TIG welding allows for more penetration into the parent material, giving the welded area more strength compared to laser welding.

Parts or assemblies that are subject to large amounts of force and stress benefit from a TIG weld. Our capabilities allow us to TIG weld with as little as 1/10th of an amp, leaving parts with minimal excess material for little secondary machining, buffing, or polishing.

Important factors for GTAW welding:

- Parts must have adequate material thickness to avoid distortion

- Parts should have thicker walls to minimize burn-through

- Weld joints or areas should be easy to access for the torch without arcing out in unwanted areas

Best-suited metals for Tungsten Inert Gas (TIG) - GTAW

| Stainless steels | Carbon steels | |

| Nickel alloys | Titanium alloys | Aluminum alloys |

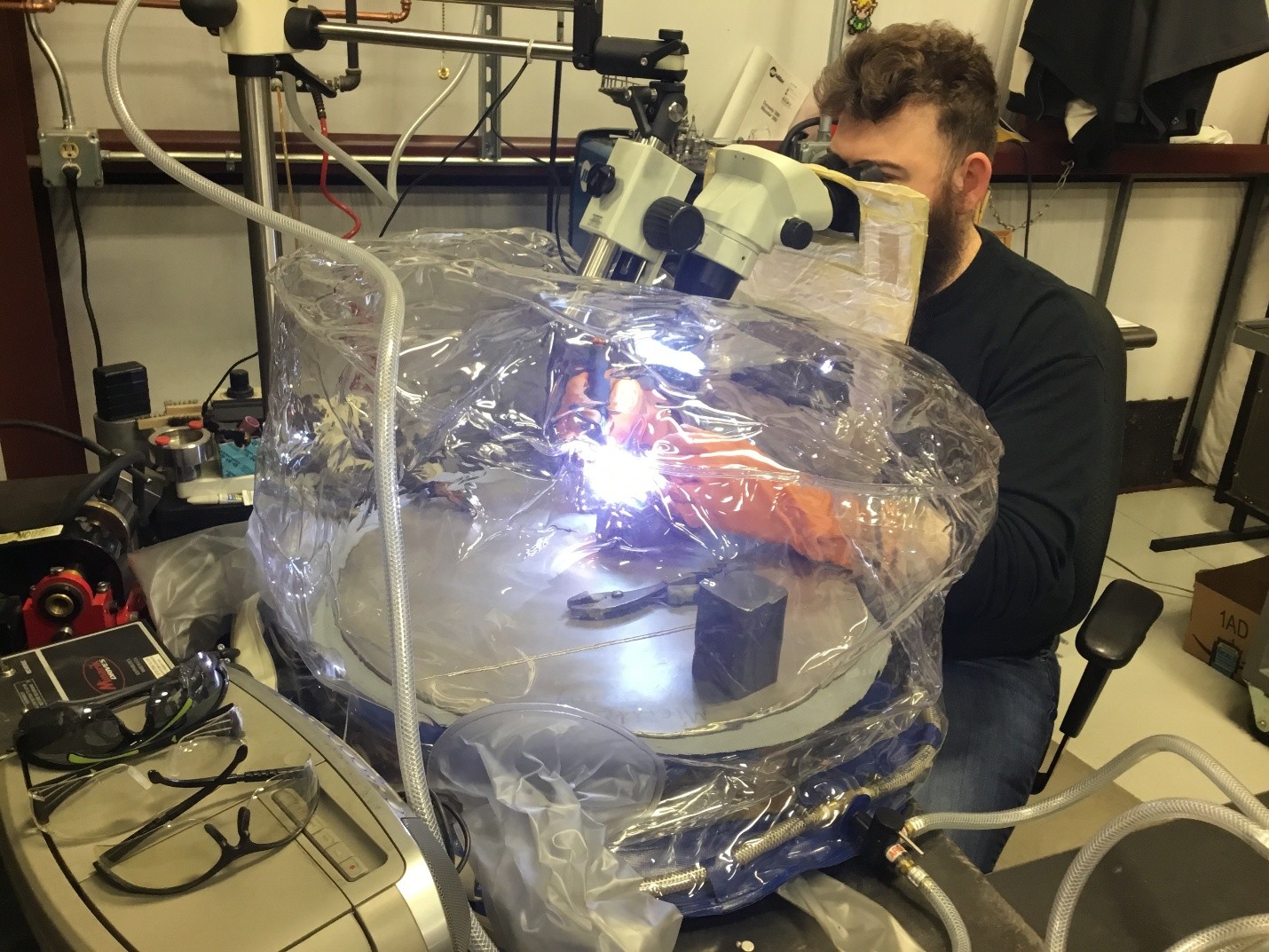

Purge Chamber Capability

Microtech offers a purge chamber that works in conjunction with the TIG and Micro TIG processes.

The purge chamber provides a completely inert atmosphere for welding reactive metals such as titanium, cobalt chrome, and molybdenum, as well as non-reactive metals like stainless steel.

The benefit of this application is that the inert atmosphere minimizes contamination of the weld, and in certain instances, reduces heat transfer and discoloration on parts where cosmetics are critical.

Additional Resources

Understanding the GTAW Welding Process

LBW vs GTAW: Strength Comparison