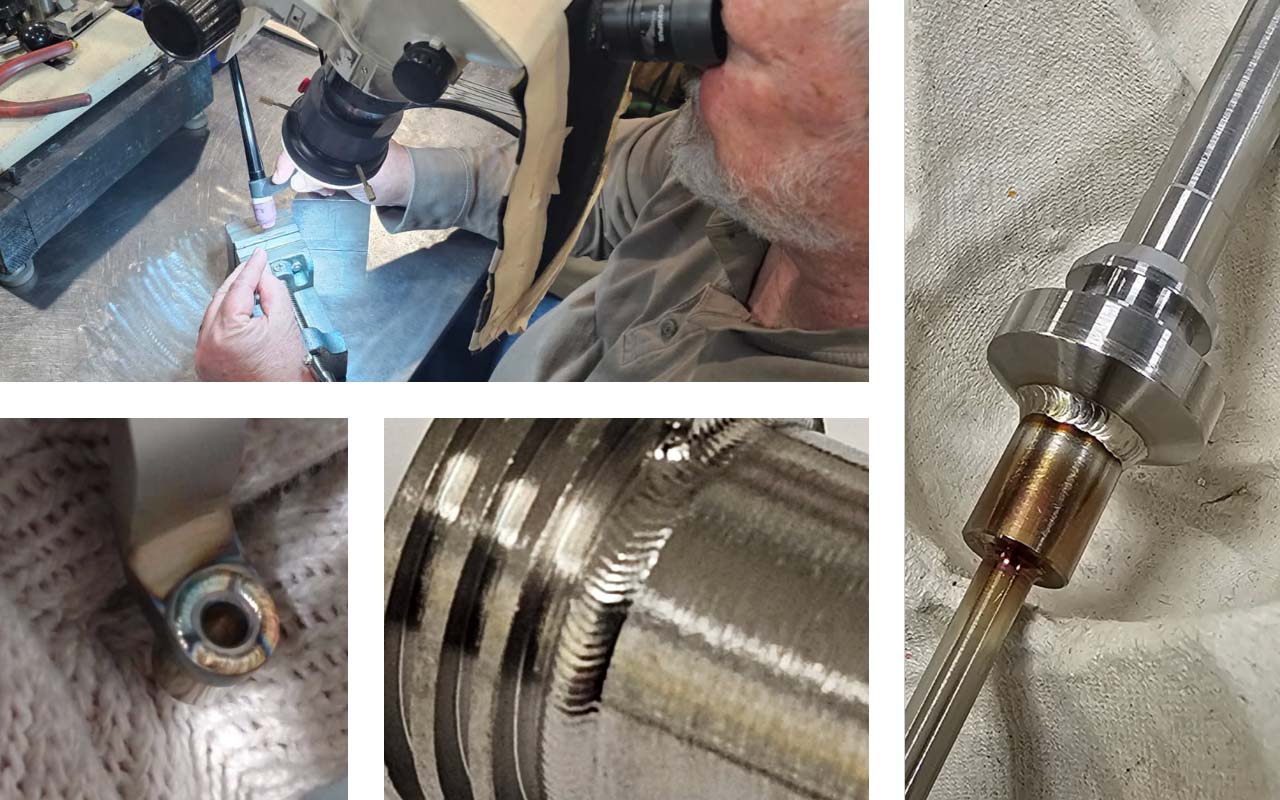

Micro TIG (GTAW)

Ultra-Precise Welding for Critical Applications

At Microtech, we specialize in Micro TIG welding - also known as Gas Tungsten Arc Welding (GTAW) - for industries where precision, reliability, and cleanliness are non-negotiable.

Whether you're producing surgical instruments, aerospace components, or sensitive electronic parts, our Micro TIG services deliver clean, strong, and distortion-free welds on even the most delicate materials.

Applications of Micro TIG

Medical | Aerospace & Defense | Electronics & Microcomponents |

| Pacemakers & implants Surgical tools Diagnostic device | Engine components Fuel system parts Sensors & avionics | Connectors Fine wires & leads Semiconductor housings |

Advantages of Micro TIG

- Very versatile - can use on most metals

- Excellent for critical components where strength and appearance are important

- Minimal heat distortion and warpage

- Maximum control for precise, high-quality welds

Best-suited metals for Micro TIG (GTAW)

| Stainless steels | Titanium alloys |

| Nickel alloys | Copper alloys |

Why Choose Microtech for Micro TIG Welding?

When it comes to welding parts measured in thousandths of an inch, experience and attention to detail are everything. Here's what sets us apart:

- Unmatched Precision: Weld beads as small as 0.010” with tolerances down to ±0.0005"

- Minimal Heat Distortion: Ideal for ultra-thin materials and temperature-sensitive alloys

- Clean, Contaminant-Free Welds: Perfect for medical and electronic applications

- AWS-Certified Expertise: Decades of specialized micro-welding experience

- Fast Turnaround Times: Critical for keeping your production schedules on track

Have a complex weld? We've probably done it.

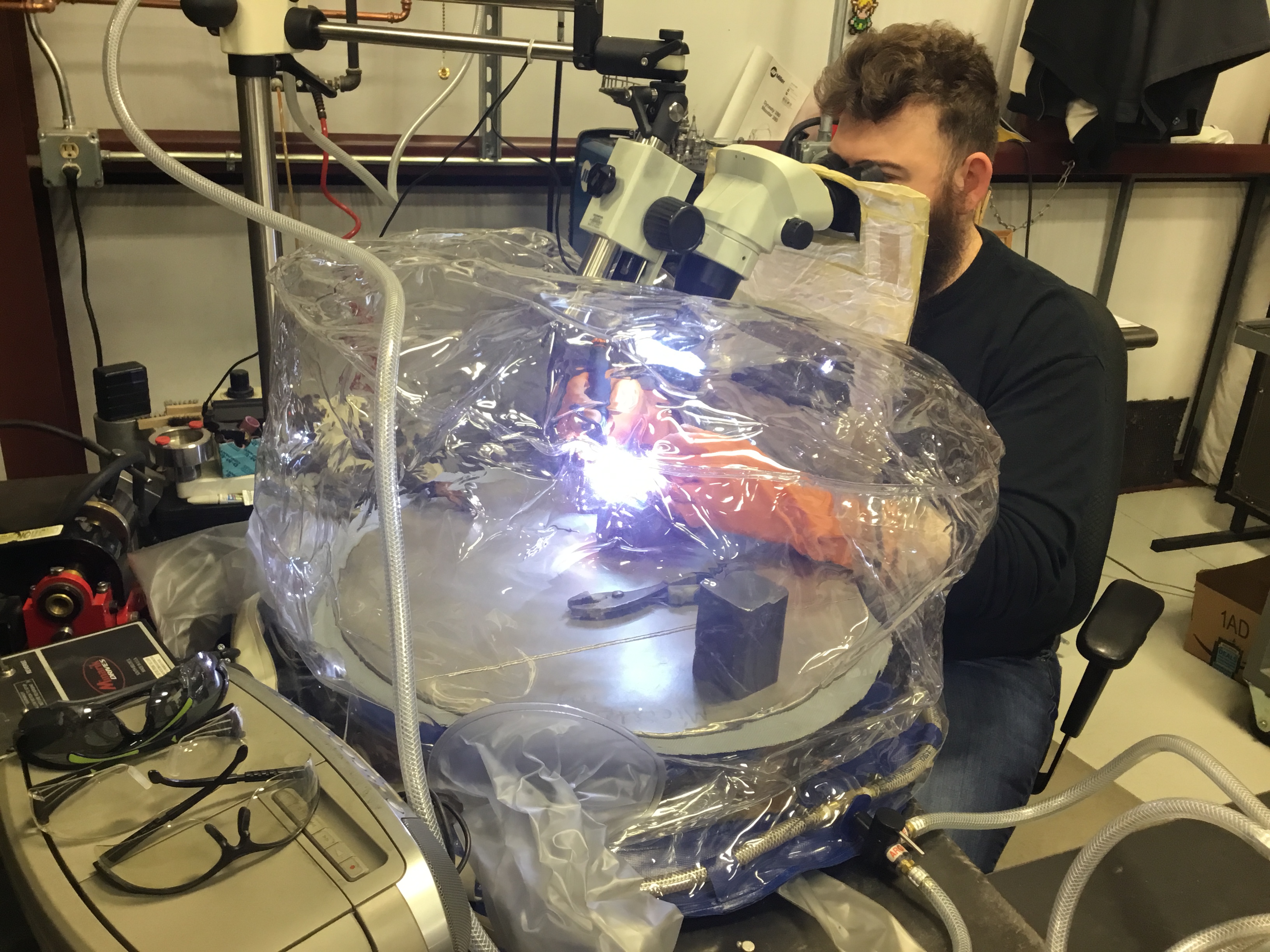

Purge Chamber Capabilities

Microtech offers a purge chamber that works in conjunction with the TIG and Micro TIG processes.

The purge chamber provides a completely inert atmosphere for welding reactive metals such as titanium, cobalt chrome, and molybdenum, as well as non-reactive metals like stainless steel.

The benefit of this application is that the inert atmosphere minimizes contamination of the weld, and in certain instances, reduces heat transfer and discoloration on parts where cosmetics are critical.

Additional Resources

Learn more about Precision TIG Welding

Laser Beam Welding vs Micro TIG