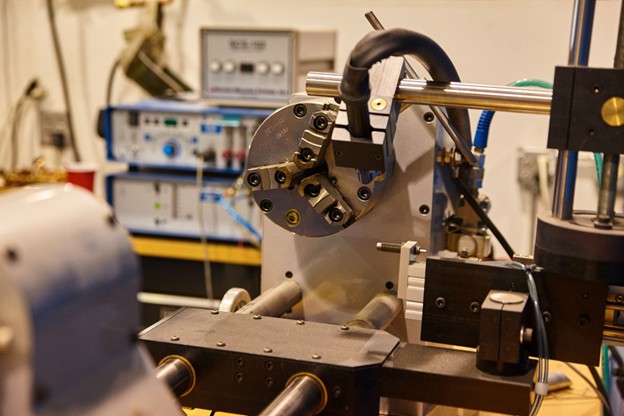

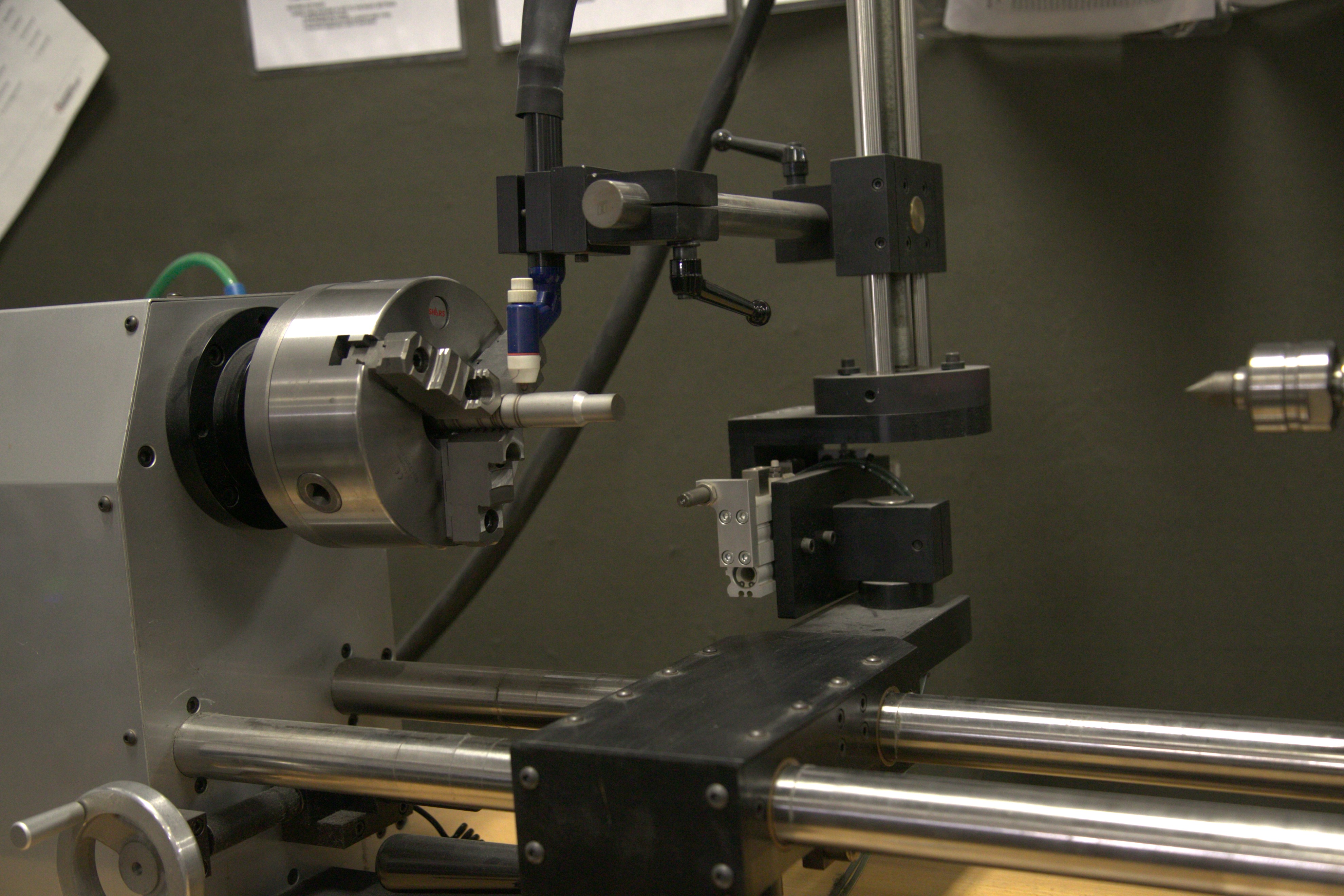

Plasma Arc Welding (PAW)

Plasma Arc Welding (PAW) is an arc welding process similar to Gas Tungsten Arc Welding (GTAW).

The electric arc is formed between an electrode and the workpiece. The main difference between GTAW and PAW is that the arc can be separated from the shielding gas envelope, creating a more concentrated plasma arc. This concentrated arc delivers deep penetration with a narrow, precise weld profile, making PAW particularly well-suited for thicker materials and structural components.

PAW is commonly used in aerospace and defense and tool & die applications where deep penetration and structural integrity are essential.

Plasma Arc Welding is offered at the Microtech Fort Wayne location.

Advantages of PAW

- Deep, narrow welds with excellent penetration

- Consistent, stable arc

- Well-suited for production environments requiring repeatability

- More precise heat control than standard TIG welding

Best-suited metals for Plasma Arc Welding (PAW)

| Stainless steels | Nickel alloys |

| Titanium alloys | Copper alloys |