Tool & Die

At Microtech Welding Corp., precision tool and die welding is the foundation of our business. Originally established as a tool and die welding job shop, we bring decades of specialized expertise in restoring, modifying, and rebuilding hardened components using advanced welding technologies. Whether you're working with worn punches, cracked cavities, or precision firearm parts, our team delivers reliable, metallurgically sound repairs that extend tool life and restore function.

Expert Welding of Tool Steels and Specialty Alloys

Our team has extensive experience welding a wide range of materials, including:

- Stellite and cobalt-chromium alloys

- Mild steels and low-carbon grades

- Stainless and alloy steels

- Custom blended filler metals for unique applications

We maintain a large inventory of specialty filler materials, matched to specific metallurgical requirements, ensuring consistent hardness, wear resistance, and structural integrity post-weld.

Advanced Welding Processes

Micro-TIG Welding (GTAW)

Ideal for delicate features and critical edges with minimal heat input, preserving heat treatment while providing precise control over weld bead size and deposition.

Laser Beam Welding (LBW)

For extremely fine repairs with heat-affected zones less than 0.010", offering excellent control for fine molds, cavities, and intricate surfaces with repeatable CNC-controlled weld profiles.

Standard GTAW for Structural Repairs

Used for large-scale repairs, fracture remediation, and major die modifications with structural buildup and recovery of cracked or broken features.

Applications

- Precision mold and die refurbishment

- Punch and die restoration

- Ejector pin hole repair

- Cavity rebuilding and dimensional corrections

- Fixture, jig, and gauge repair

- Tooling upgrades and design alterations

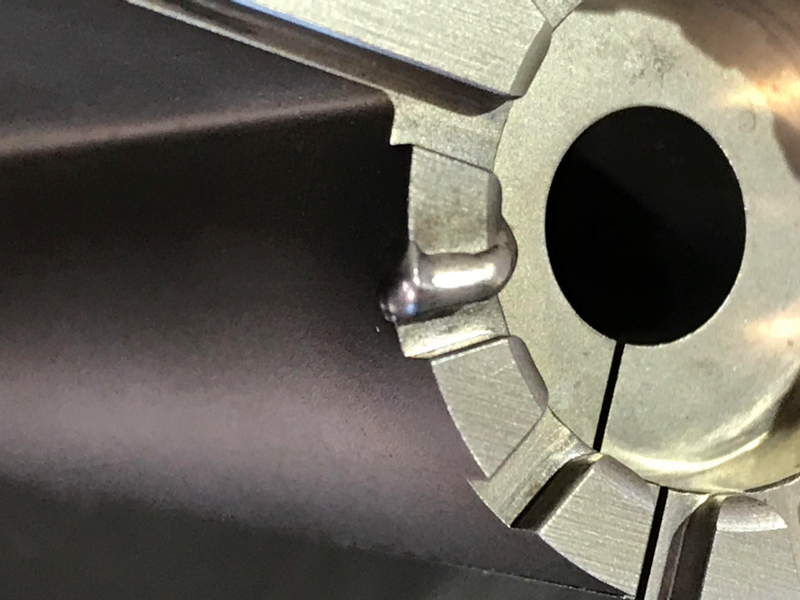

Licensed Firearm Welding & Repair

As a facility with Federal Firearms Licensee (FFL) and Special Occupational Tax (SOT) certification, Microtech Welding is authorized to perform weld repairs on firearm components, including slides, receivers, barrels, and suppressor parts. We maintain strict confidentiality and compliance in all FFL-regulated services.

Why Choose Microtech for Tool & Die Repair?

- Industry-rooted expertise since our founding

- Extensive filler metal library for optimal metallurgical matches

- Advanced Micro-TIG and laser welding capabilities

- FFL-certified and ISO 13485:2016 compliant facility

- AWS D17.1 certified welders

- In-house metal sectioning lab for weld testing and validation

Whether you're restoring high-wear tooling, modifying intricate dies, or rebuilding precision components, Microtech Welding Corp. offers durable, high-quality weld repairs that meet the demanding standards of the tool and die industry.