Firearms

Microtech Welding Corp. is proud to offer licensed firearm repair and manufacturing services under our Federal Firearms License (FFL) and Special Occupational Tax (SOT) certification. These credentials, granted by the Bureau of Alcohol, Tobacco, Firearms, and Explosives (ATF), authorize us to legally perform both precision firearm repairs and manufacture NFA-regulated items, including firearm suppressors.

Backed by over 100 years of combined welding experience and equipped with advanced processes—like Laser Beam Welding (LBW) and Gas Tungsten Arc Welding (GTAW/Micro TIG)—Microtech delivers unmatched precision, quality, and compliance for firearm owners, collectors, gunsmiths, and defense manufacturers.

Licensed to Repair and Manufacture Firearms

Through our FFL and SOT certifications, Microtech Welding Corp. is authorized to:

Perform high-integrity repairs on handguns, rifles, shotguns, and collectible firearms

Manufacture and service firearm suppressors and other NFA-regulated components

Work with military, law enforcement, and commercial firearms manufacturers

Handle custom-built and modified weapon systems

We work directly with firearm owners, gunsmiths, and OEMs to ensure every weld meets strict safety, mechanical, and legal standards.

Why Use Laser & Micro TIG Welding for Firearm Work?

Firearms endure repeated stress, heat, and friction, which can cause:

Cracks in frames or barrels

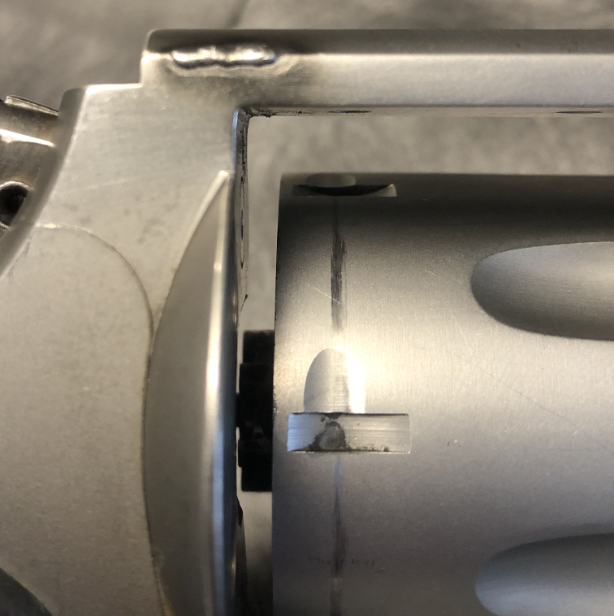

Wear on small internal components (e.g., ejectors, latches, and triggers)

Deformation or fatigue in suppressor baffles and end caps

Our precision welding techniques effectively restore structural integrity while protecting surrounding components and maintaining performance.

Laser Beam Welding (LBW) for Firearms

Laser welding is a low-heat, high-precision process perfect for delicate or dimension-critical firearm components.

Key Benefits:

Pinpoint accuracy for micro-scale repairs

Clean welds with minimal heat-affected zones

Ideal for restoring tight tolerances in receivers, rails, and slides

Non-contact process protects fragile or heat-sensitive materials

Micro TIG Welding (GTAW) for Firearms

Micro TIG welding provides stronger welds for parts that require material buildup or structural reinforcement—often necessary in frame repair, barrel lugs, or suppressor construction.

Key Benefits:

Excellent bead control and penetration

Works with a wide range of alloys (tool steel, stainless, carbon steel, titanium)

Minimal distortion of the base material

Ideal for suppressor baffle and tube fabrication

Firearm Suppressor Welding & Repair

As a certified SOT manufacturer, Microtech Welding has direct experience fabricating and repairing suppressor components, including:

- Baffle stacks

- End caps

- Mounts and threads

- Monolithic cores

Whether you're building a prototype or repairing a high-use suppressor, our in-house welding and inspection capabilities ensure safe and repeatable results for every part.

Certified, Compliant, and Confidential

All firearm-related work at Microtech is handled with strict adherence to federal, state, and local laws, including:

Secure handling and storage of all firearms and suppressor parts

ATF-compliant record keeping and reporting

Discreet service for law enforcement, collectors, and private clients

Flexible Repair & Manufacturing Services

We offer multiple ways to get your firearm or suppressor parts serviced:

Walk-in firearm repair during regular business hours

Appointments by phone for custom jobs or consultations

Online contact form for estimates, turnaround times, or compliance questions

Who We Serve

Firearm owners needing reliable, non-invasive repair

Collectors and gunsmiths restoring legacy or custom weapons

OEMs and defense contractors seeking welding for suppressor or firearm components

Law enforcement and military agencies with specialty repair needs

Precision Firearm Services You Can Trust

aftsman-level attention to detail.

Contact us today to discuss your project or schedule a consultation.