Laser Beam Welding Benefits Device Fabrication

Recently, the Medical Device and Diagnostic Industry published an article about welding for medical device fabrication. Medical devices, instruments, and implants are all made from extremely thin, delicate materials. Because of this, traditional welding methods, such as GTAW (Gas Tungsten Arc Welding), can warp them or change their cosmetic structure. Laser Beam Welding (LBW) is a great alternative to this issue. It is extremely accurate, inputs minimal heat, and can achieve welds even smaller than Micro GTAW. Opting for LBW not only delivers a better product but also reduces production costs. Other benefits include increased design flexibility, less scrap material, and reduced project time.

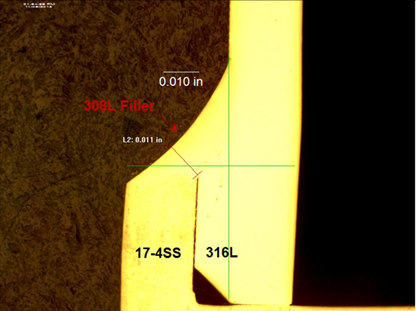

Operators observe and control the welding process through a microscope.