Ensuring Aerospace-Grade Weld Integrity: Inside Microtech Welding Corp’s Metal Sectioning Lab

In the aerospace, defense, and medical device sectors, weld quality isn’t just a performance metric. It’s a critical requirement. At Microtech Welding Corp, precision welding is supported by an advanced in-house Metal Sectioning Lab, built to validate weld integrity and penetration using metallographic testing. For engineers, buyers, and QA teams in regulated industries, this lab represents a key differentiator in Microtech’s weld process validation and quality control management.

What Is Metal Sectioning and Why Does It Matter?

Metal sectioning, also known as metallographic cross-sectioning, is a testing process used to assess internal weld structure. It enables Microtech’s technicians and welders to examine penetration depth, fusion zones, heat-affected areas, porosity, and inclusions—ensuring that every weld meets specifications before it enters critical service.

With in-house sectioning, Microtech has full control over process development, nonconformity detection, and real-time corrective feedback, so you don't have to rely on slow, third-party labs.

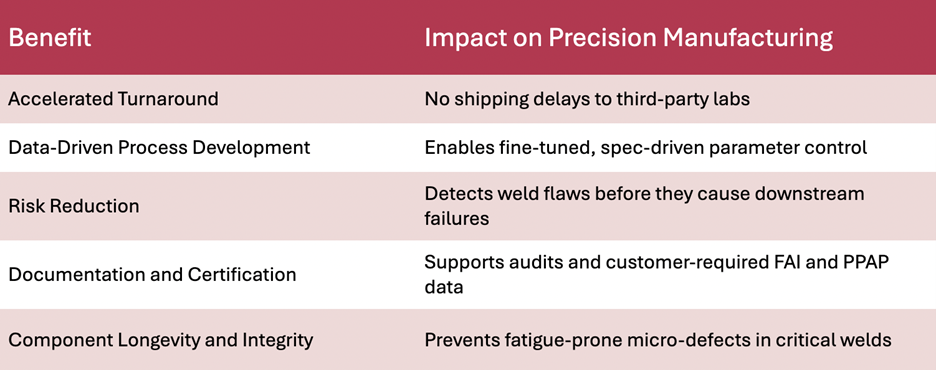

Why Metal Sectioning Adds Value

Key Functions of the Metal Sectioning Lab

1. Precision Weld Process Validation

Before any production weld is released, Microtech uses its metallography lab to qualify welding parameters, materials, and joint designs. Cross-sectioned coupons are analyzed under magnification to confirm that penetration meets the tolerances outlined in AWS D17.1 standards.

2. Real-Time Feedback for Process Optimization

Because the lab is on-site, we can rapidly test, section, and iterate welding setups within hours, not days or weeks. This closed-loop system accelerates design-of-experiment (DOE) efforts and improves first-pass yield.

3. Batch-Level Quality Assurance

For serialized aerospace and medical components, Microtech uses sectioning to confirm repeatability from lot to lot. Visual indicators of burn-through, undercutting, or insufficient fusion are caught before they affect production runs.

4. Documented Compliance and Traceability

All results from sectioning are digitally archived and traceable to part numbers, lot codes, and operator certifications, supporting compliance with ISO 13485:2016 protocols.

Why Sectioning Adds Value for Aerospace, Defense, and Medical Device Manufacturing

Microtech Welding Corp’s integrated approach—combining Micro TIG, Laser Beam Welding, in-house metallography, and more—provides an unmatched level of precision, control, and documentation. For OEMs and Tier 1 suppliers, this means fewer quality concerns, lower rework rates, and welds that meet or exceed expectations.

Contact Microtech Welding

Looking for a high-quality weld? Microtech’s Metal Sectioning Lab gives you the data confidence your program demands.