In the world of micro-welding, quality isn’t just a guiding principle; it’s the difference between a part that performs flawlessly and one that fails in the field. When you’re working at a scale where a weld bead can be thinner than a strand of hair, there is no room for approximation, shortcuts, or “close enough.” Every decision, every process, every skill applied must align to deliver reliable, repeatable, inspection-ready welds.

But what does “quality first” actually look like in micro-welding? It’s more than checking boxes—it’s a mindset that influences every step of the job.

1. Quality Starts Before the Weld

A high-quality weld is determined long before the welder turns on a torch or activates a laser. It begins with:

- Understanding the end-use application

- Knowing the performance requirements

- Confirming material compatibility

- Evaluating joint design and fit-up

If a part is destined for a medical implant, the requirements are different than those if it’s used in a firearm, aerospace assembly, or electronic device. This pre-weld evaluation ensures the approach matches the demands.

Even microscopic inconsistencies in joint preparation can affect strength, heat input, and final appearance. Precision cleaning, proper alignment, and careful fixture design are all essential.

2. Skilled Hands Matter as Much as Technology

Advanced equipment ensures consistency—but it doesn’t replace the welder.

Micro-welding is a craft that demands:

- Steady hand control at extremely small scales

- The ability to manage heat input down to fractions of a second

- Experience recognizing subtle visual cues during the weld

Machines can automate, but they cannot interpret. A skilled welder knows when the puddle is behaving differently, when the parent material is responding unusually, and how to adjust in real time.

3. Controlled Heat Input Is Critical

Heat is both necessary and potentially damaging. Too much heat can distort parts, weaken joints, or alter surface finish. Too little can lead to poor penetration and weak bonds.

“Quality first” means:

- Using the smallest heat footprint possible

- Monitoring heat input with strict consistency

- Applying filler only when needed and only precisely where needed

This ensures strong, clean, uniform welds that preserve material integrity and cosmetic appearance.

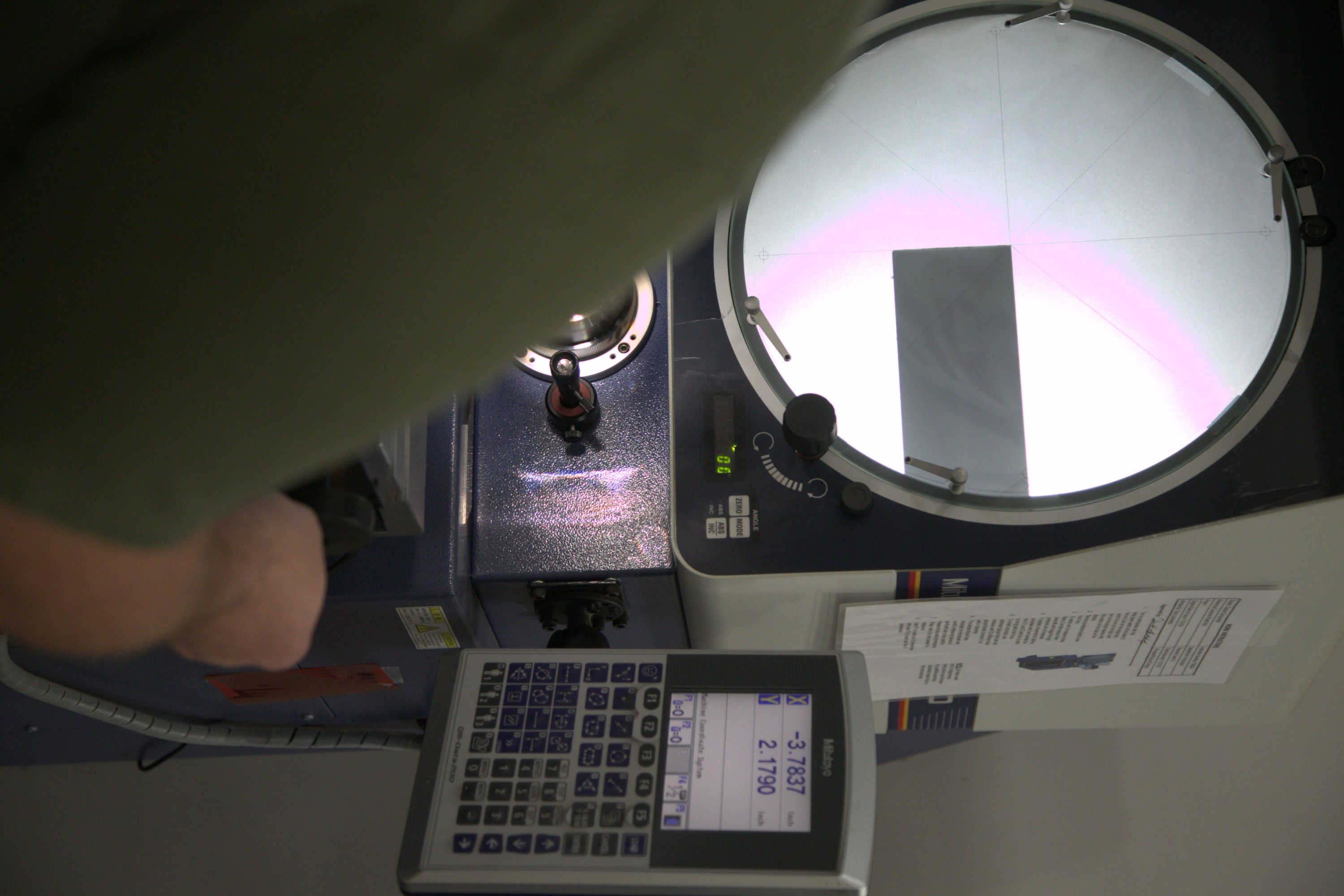

4. Inspection Isn’t the Final Step—It Happens Throughout

Quality isn’t confirmed; it’s maintained.

At Microtech Welding, inspection includes:

- Pre-weld verification

- Monitoring during welding

- Post-weld visual and magnified inspection

Even the tiniest pore or hairline crack is unacceptable.

If it isn’t perfect, it doesn’t leave the shop.

5. Repeatability Proves Quality

Micro-welding isn’t just about making one part right. It’s about making the next 500 parts identical.

That comes from:

- Documented welding parameters

- Stable, repeatable work environments

- Rigid process control

- Consistent training and workmanship standards

6. Quality Is a Partnership with the Customer

Finally, “quality first” means collaboration.

Customers rely on clarity, communication, and guidance from experts who understand the practical realities of welding at the micro scale.

Whether we are troubleshooting part design, refining a prototype, or scaling into production, we work together to make sure the weld meets performance and manufacturing goals.

Quality Is Not Just a Standard. It’s a Promise.

Micro-welding demands precision. But more than that, it demands integrity. Every weld represents trust, trust that the part will function, last, and perform exactly as expected.

That’s what “quality first” means.

It means we do it right, every time, without exception.